Global Tankcom Sdn Bhd

公司办公地址:

Suite 2-7-5, No. 2, 7th Floor,

Wisma Menjalara,

Jalan 7A/62A,

Bandar Menjalara,

52200 Kuala Lumpur,

Malaysia.

分公司及仓库:

No.17, Jalan Gitar 33/3,

Seksyen 33,

40400 Shah Alam,

Selangor, Malaysia

+6012-390 6878

+60123906878

Wastewater Engineering Services

| 上一页 | 1 / 5 | 下一页 |

Wastewater is a by-product that is generated by various industries with its own unique contamination that requires an appropriate designed treatment system before being recycled or discharged into the environment.

Global Tankcom’s expertise covers the treatment of industrial wastewater and sewage treatment.

We offer our customers a comprehensive range of chemicals, products, system, and services to cover a total quality solution and management.

Global Tankcom with the expertise of each discipline engineers delivers high-end detailed design with adequate design calculation and technical specification documents for each unit operations. We have skilful CAD designers to produce detailed P&ID, 3D models and 2D shop drawings.

Global Tankcom provides comprehensive EPCC solution for wastewater and sewage treatment system. Global Tankcom, takes care of the entire project, covering engineering design, procurement of all necessary machines, equipment, materials and parts, construction, testing, and commissioning the plant.

Global Tankcom are specialized in designing and building various wastewater treatment plants as per DOE requirement and standards.

Our core expertise in type of wastewater treatment as the following:

Global Tankcom’s expertise covers the treatment of industrial wastewater and sewage treatment.

We offer our customers a comprehensive range of chemicals, products, system, and services to cover a total quality solution and management.

Global Tankcom with the expertise of each discipline engineers delivers high-end detailed design with adequate design calculation and technical specification documents for each unit operations. We have skilful CAD designers to produce detailed P&ID, 3D models and 2D shop drawings.

Global Tankcom provides comprehensive EPCC solution for wastewater and sewage treatment system. Global Tankcom, takes care of the entire project, covering engineering design, procurement of all necessary machines, equipment, materials and parts, construction, testing, and commissioning the plant.

Global Tankcom are specialized in designing and building various wastewater treatment plants as per DOE requirement and standards.

Our core expertise in type of wastewater treatment as the following:

a. Dairy production wastewater treatment plant (WWTP)

Dairy production is one of the rapid growing industries with major water consumption. Increased in the demand for dairy products, increased the water consumption hence the wastewater production increases. Wastewater as byproduct generated during processing of milk and other dairy products.

The process water requires to be used in milk processing where milk is transformed into cheese, yogurt or butter, for the purpose of cooling, cleaning etc. In cheese, yogurt and butter production, wastewater is being generated from equipment cleaning, cooling the curds and from the whey separation during cheese making process. Apart from the production waste, services as cleaning and sanitation for dairy facilities which requires extensive amount of water contributes to dairy wastewater.

Dairy wastewater contains high concentrations of organic and inorganic substances that cause eutrophication in water bodies. Significant contaminants in dairy wastewa

ter are Chemical Oxygen Demand (COD), Biological Oxygen Demand (BOD), Total Suspended Solids (TSS), Fatty acid (FOG), Total Phosphorus (TP), Total Nitrogen (TN) etc. These contaminants are difficult to treat in single step conventional treatment technique.

As a pretreatment, gravity separator is used to remove the emulsified/solid fatty acid from the stream. Gravity will be used as primary force for the separation, as the fatty acids are less dense than water, it will float on the surface. A skimming mechanism is used to skim the floating FOG and dispose separately. Apart from gravity separator, Dissolved Air Floatation (DAF) also can be used as physical-chemical treatment for the removal of FOG, Total Suspended Solids (TSS) and colloids. With proper chemical adjustment, the DAF with good white-water formation could be able to remove 70~80% of FOG and 90% of TSS.

.png)

Based on COD/BOD ratio, the type of wastewater treatment will be determined for better treated water quality for dairy industries. Commonly, dairy wastewater is high loading in organic impurities such as Biological Oxygen Demand (BOD), nutrients, where preferred treatment method is biological process.

Type of Biological Treatments in dairy wastewater system:

- The Sequencing Batch Reactor (SBR) is preferred in dairy wastewater treatment because of its various loading capabilities, mostly low-strength and effluent flexibility.

- An aerobic SBR is an excellent example of the combination of activated sludge granulation with dairy effluent treatment.

- Moving Bed Biofilm Reactor (MBBR) also shows very high performance when applied to dairy wastewaters: Organic Loading Rate (OLR) increases dozens of times compared to conventional activated sludge systems. A novel MBBR with free-floating plastic elements (with a density slightly less than 1.0 kg/m3) may give 60%~ 80% Chemical Oxygen Demand (COD) reduction.

- Upflow Anaerobic Sludge Blanket (UASB) reactor is the most applied as anaerobic method in dairy wastewater treatment. UASB is most suitable for high COD loading (COD > 30000 mg/L). In UASB system, the average total and soluble COD removals were above 95%, whilst producing biogas rich in methane, it diminishes overall sludge production, and obtains a high quality effluent.

With the wide range of available treatments for dairy wastewater, Global Tankcom study on client’s wastewater constituents and expert in providing integrated solution to treat the specific wastewater.

b. Petrochemical wastewater treatment and well produced water

Oil refineries and gas processing plants generate wastewater from various unit operations. The sources of petrochemical wastewater are diverse and can originate from oilfield production, crude oil refinery plants, the olefin process plants, refrigeration, and energy unities. This wastewater typically contains hydrocarbons (HC), volatile organic compounds (VOCs), heavy metals, and other contaminants associated with petroleum refining.

The produced water that returns to the surface as wastewater during oil and gas production contains hydrocarbon from the deposit as well as naturally occurring toxic substance like arsenic and radium, salts, heavy metals, and chemical additives injected into the well to facilitate extraction.

A proper management or treatment is needed for reuse, discharge, or final disposal to minimize their impact on the environment. Due to the complexity of the wastewater composition, petrochemical wastewater requires combination of different treatment method. At some unique cases, the treatment requires multistage chemical or biological treatment based on the incoming composition loading and the treated water quality.

For the pretreatment, Tilted Plate Interceptor (TPI) or Corrugated Plate Interceptor (CPI) is used as oil-water separator before it passes down to further treatment such as chemical treatment and biological treatment. TPI and CPI uses mechanical mechanism to separate the oil from the water via gravity force. With the tilted and corrugated plate in the system, it increases efficient surface area where it allows the O&G to float on the surface. The floating O&G will be skimmed via oil skimmer and collect separately for disposal.

Following treatment with TSS and heavy metal removal, coagulation-flocculation process is required. Due to the various of heavy metal presence in the wastewater, an optimum pH must be obtained based on the metal precipitation graph. Global Tankcom team is experts in conducting jar test to determine the suitable metal precipitator, coagulant, and flocculant. A sedimentation process is required to remove the flocs and colloidal that has formed in coagulation and flocculation processes. In petrochemical wastewater, the metal flocs (Barium, Boron, Aluminium, Iron, Lead, Zinc, Copper, Nickel, Chromium, Cadmium, Mercury, etc) are considered heavier than other industries hence, Lamella clarifier is most suitable for heavier metal flocs to get sedimented and cost-effective compared to DAF and sedimentation tank. The working mechanism for Lamella clarifier is easier and operator-friendly, also it is safer especially at brownfield. The inclined plates increase the solid settlement rate or Solid Loading Rate (SLR) as the surface is high compared to conventional sedimentation tank.

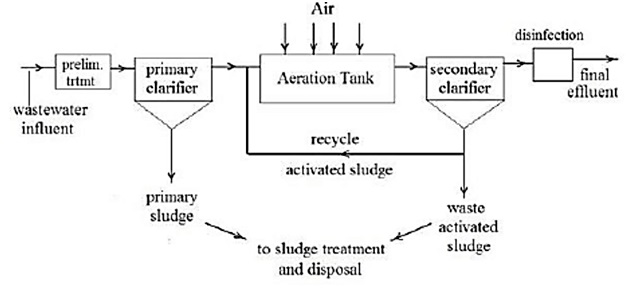

Once the Oil & Gas (O&G), Total Suspended Solids (TSS), heavy metal and most of the toxic constituents has been removed, the wastewater can be treated in the biological process if the organic loading is still high and exceeded the discharge limit. Some cases, after the chemical treatment, the wastewater can be discharged or proceed to reclamation process with less/no organic loading. In biological treatment, aeration method is widely used with Membrane Bio Reactor (MBR) to increases the performance of the biological system. The activated sludge process or aeration is accomplished by umping the air into a tank and promotes the growth of microorganism in the wastewater. The aerobic microorganism consumes on pollutants (organic loading) to survive and concurrently reduces the organic loading in the stream.

As a final stage, polishing system is essential for achieving the stringent discharge quality as stated in DOE. In polishing system, activated carbon filtration and sand filtration is provided to enhance organic matter, odour removal as well as suspended solid removal, respectively.

The produced water that returns to the surface as wastewater during oil and gas production contains hydrocarbon from the deposit as well as naturally occurring toxic substance like arsenic and radium, salts, heavy metals, and chemical additives injected into the well to facilitate extraction.

A proper management or treatment is needed for reuse, discharge, or final disposal to minimize their impact on the environment. Due to the complexity of the wastewater composition, petrochemical wastewater requires combination of different treatment method. At some unique cases, the treatment requires multistage chemical or biological treatment based on the incoming composition loading and the treated water quality.

For the pretreatment, Tilted Plate Interceptor (TPI) or Corrugated Plate Interceptor (CPI) is used as oil-water separator before it passes down to further treatment such as chemical treatment and biological treatment. TPI and CPI uses mechanical mechanism to separate the oil from the water via gravity force. With the tilted and corrugated plate in the system, it increases efficient surface area where it allows the O&G to float on the surface. The floating O&G will be skimmed via oil skimmer and collect separately for disposal.

Following treatment with TSS and heavy metal removal, coagulation-flocculation process is required. Due to the various of heavy metal presence in the wastewater, an optimum pH must be obtained based on the metal precipitation graph. Global Tankcom team is experts in conducting jar test to determine the suitable metal precipitator, coagulant, and flocculant. A sedimentation process is required to remove the flocs and colloidal that has formed in coagulation and flocculation processes. In petrochemical wastewater, the metal flocs (Barium, Boron, Aluminium, Iron, Lead, Zinc, Copper, Nickel, Chromium, Cadmium, Mercury, etc) are considered heavier than other industries hence, Lamella clarifier is most suitable for heavier metal flocs to get sedimented and cost-effective compared to DAF and sedimentation tank. The working mechanism for Lamella clarifier is easier and operator-friendly, also it is safer especially at brownfield. The inclined plates increase the solid settlement rate or Solid Loading Rate (SLR) as the surface is high compared to conventional sedimentation tank.

Once the Oil & Gas (O&G), Total Suspended Solids (TSS), heavy metal and most of the toxic constituents has been removed, the wastewater can be treated in the biological process if the organic loading is still high and exceeded the discharge limit. Some cases, after the chemical treatment, the wastewater can be discharged or proceed to reclamation process with less/no organic loading. In biological treatment, aeration method is widely used with Membrane Bio Reactor (MBR) to increases the performance of the biological system. The activated sludge process or aeration is accomplished by umping the air into a tank and promotes the growth of microorganism in the wastewater. The aerobic microorganism consumes on pollutants (organic loading) to survive and concurrently reduces the organic loading in the stream.

As a final stage, polishing system is essential for achieving the stringent discharge quality as stated in DOE. In polishing system, activated carbon filtration and sand filtration is provided to enhance organic matter, odour removal as well as suspended solid removal, respectively.

c. Automotive (anodizing) and Metalworking wastewater treatment plant (WWTP)

Automotive manufacturing and metalworking industries generate wastewater from metal cutting and finishing processes such as hard anodizing and colour anodizing. Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Hard anodizing helps in the functional refinement of aluminium alloys and other metals while colour anodizing is a surface treatment process that enhances the appearance and performance of metals, typically aluminium. There are plenty of chemicals will be used in the process as electrolyte, for example chromic acid used to form a fine, thin, and non-conductive anodized coating around the metal while sulphuric acid used to from a thicker oxide of aluminium or anodized layer around the aluminium component. The toxic effluents from the anodizing industries are rich in heavy metals like aluminium, magnesium, nickel, zinc, iron and phosphates, colour, Total Suspended Solids as well as very low pH.

Advanced technology like nanofiltration, reverse osmosis and adsorption can effectively remove the variety of pollutants in the wastewater, achieving removal rate of > 90%. Apart from that, Global Tankcom provides full study on cost effectiveness also reuse of the anodising/metal working wastewater in other aspects.

Conventional treatment such as physicochemical treatment with tertiary treatment treats the anodizing wastewater up to discharge water quality. As a pretreatment, filtration is required to remove the debris and other suspended materials. Followed by pH adjustment using NaOH, and suitable coagulant in coagulation process to precipitate the heavy metals. The suitable chemical and chemical optimization can be determined by jar testing. After the settlement using lamella clarifier or sedimentation tank, the treated water can be processed to recycle, or discharge based on client’s requirement.

d. Semiconductor wastewater treatment plant (WWTP)

In the semiconductor industry, wafer fabs generate a wide variety of different production wastewaters and spent production solutions due to complex manufacturing processes such as chemical mechanical polishing (CMP), or various rinsing or etching processes performed on wafers. These wastewaters and solutions contain several potentially problematic ingredients such as:

· Complexing agents/ chelates - such as cyanide or PBTC

· Organo-nitrogen compounds - such as pyrazole, triazoles, or tetramethylammonium hydroxide (TMAH)

· Toxic compounds

· Organic compounds with poor biodegradability

· Excess H2O2 or ozone from rinsing processes

· Spent production solutions such as sulfuric acid (H2SO4) contaminated with H2O2 from etching processes with piranha acid / peroxomonosulfuric acid.

These substances enter the wastewater system of the fab after the manufacturing process individually, or in the worst case as a mixture. This complex mixture and the individually already problematic ingredients in semiconductor manufacturing pose difficult tasks for conventional methods of wastewater treatment, especially when an economical, environmentally friendly, and compact treatment is required.

Each complexed wastewater goes through different type of treatment before it gets discharge or reclaimed.

Type of treatment: Neutralization treatment, Hydro Fluoride removal treatment, TMAH removal treatment, Heavy metal removal (copper wastewater treatment)

(i) Neutralization Treatment is a process to adjust the pH to neutral which is pH range of 6~8 before discharge into the environment or for reclaim purposes. Neutralization process happen via chemical dosing of acid or alkali into the stream based on incoming pH value.

(ii) Hydrofluoric (HF) is most common and hazardous waste in semiconductor industries. Conventional method for Hydrofluoric Treatment is two stage precipitation, coagulation-flocculation, clarification, sedimentation, and sludge handling system, to meet effluent quality requirements set by client.

(iii) Tetramethylammonium hydroxide (TMAH) is an ammonium salt used in photolithography process where it uses to manufacture integrated circuits (IC), printed circuit boards (PCB), and flat panel displays (LCD). TMAH can be removed via biological processes i.e., aerobic, or anaerobic. Biodegradation of TMAH is efficient during hydrolysis acidification-aerobic process. Apart from that, ozonation is a new method used to degrade TMAH content in the wastewater stream. It is an oxidation action of free radicals created by ozone decomposition in water. The ozone (O3) removes pollutants more efficiently than chemical oxidants.

Advanced technology like nanofiltration, reverse osmosis and adsorption can effectively remove the variety of pollutants in the wastewater, achieving removal rate of > 90%. Apart from that, Global Tankcom provides full study on cost effectiveness also reuse of the anodising/metal working wastewater in other aspects.

Conventional treatment such as physicochemical treatment with tertiary treatment treats the anodizing wastewater up to discharge water quality. As a pretreatment, filtration is required to remove the debris and other suspended materials. Followed by pH adjustment using NaOH, and suitable coagulant in coagulation process to precipitate the heavy metals. The suitable chemical and chemical optimization can be determined by jar testing. After the settlement using lamella clarifier or sedimentation tank, the treated water can be processed to recycle, or discharge based on client’s requirement.

d. Semiconductor wastewater treatment plant (WWTP)

In the semiconductor industry, wafer fabs generate a wide variety of different production wastewaters and spent production solutions due to complex manufacturing processes such as chemical mechanical polishing (CMP), or various rinsing or etching processes performed on wafers. These wastewaters and solutions contain several potentially problematic ingredients such as:

· Complexing agents/ chelates - such as cyanide or PBTC

· Organo-nitrogen compounds - such as pyrazole, triazoles, or tetramethylammonium hydroxide (TMAH)

· Toxic compounds

· Organic compounds with poor biodegradability

· Excess H2O2 or ozone from rinsing processes

· Spent production solutions such as sulfuric acid (H2SO4) contaminated with H2O2 from etching processes with piranha acid / peroxomonosulfuric acid.

These substances enter the wastewater system of the fab after the manufacturing process individually, or in the worst case as a mixture. This complex mixture and the individually already problematic ingredients in semiconductor manufacturing pose difficult tasks for conventional methods of wastewater treatment, especially when an economical, environmentally friendly, and compact treatment is required.

Each complexed wastewater goes through different type of treatment before it gets discharge or reclaimed.

Type of treatment: Neutralization treatment, Hydro Fluoride removal treatment, TMAH removal treatment, Heavy metal removal (copper wastewater treatment)

(i) Neutralization Treatment is a process to adjust the pH to neutral which is pH range of 6~8 before discharge into the environment or for reclaim purposes. Neutralization process happen via chemical dosing of acid or alkali into the stream based on incoming pH value.

(ii) Hydrofluoric (HF) is most common and hazardous waste in semiconductor industries. Conventional method for Hydrofluoric Treatment is two stage precipitation, coagulation-flocculation, clarification, sedimentation, and sludge handling system, to meet effluent quality requirements set by client.

(iii) Tetramethylammonium hydroxide (TMAH) is an ammonium salt used in photolithography process where it uses to manufacture integrated circuits (IC), printed circuit boards (PCB), and flat panel displays (LCD). TMAH can be removed via biological processes i.e., aerobic, or anaerobic. Biodegradation of TMAH is efficient during hydrolysis acidification-aerobic process. Apart from that, ozonation is a new method used to degrade TMAH content in the wastewater stream. It is an oxidation action of free radicals created by ozone decomposition in water. The ozone (O3) removes pollutants more efficiently than chemical oxidants.

(iv) Heavy metal removal in semiconductor is a conventional method using metal precipitation, coagulation-flocculation, clarification, sedimentation, and sludge handling system. To be specific, copper is the common heavy metal found in CMP process. The copper wastewater from the production stream can be classified as concentrated and diluted copper waste. Based on the quantity and quality of the copper wastewater produced, Global Tankcom can suggest in disposing or treating the copper wastewater is profitable.

Global Tankcom provides complete wastewater treatment plant (WWTP) which complies with regulations of DOE standard A or Standard B discharge quality.

Location: Kuala Lumpur: Bukit Bintang, Titiwangsa, Setiawangsa, Wangsa Maju, Batu, Kepong, Segambut, Lembah Pantai, Bandar Tun Razak, Cheras, Ampang, Batu Caves, Damansara, Sentul, Sungai Besi Selangor: Gombak, Hulu Langat, Hulu Selangor, Klang, Kuala Langat, Kuala Selangor, Petaling, Sabak Bernam, Sepang, Shah Alam, Ampang Jaya, Kajang, Bangi, Kota Damansara, Petaling Jaya, Putrajaya, Cyberjaya, Bandar Saujana Putra, Selayang, Subang Jaya, Puchong, Kota Damansara, Sungai Long, Gombak District • Hulu Langat District • Hulu Selangor District • Klang District • Kuala Langat District • Kuala Selangor District • Petaling District • Sabak Bernam District • Sepang District • Petaling Jaya • Shah Alam • Ampang • Assam Jawa • Bagan Lalang • Balakong • Bangi • Banting • Batang Kali • Batu Arang • Batu Caves • Beranang `• Bestari Jaya • Broga • Bukit Lanjan • Bukit Raja • Bukit Rotan • Bukit Tagar • Cheras • Cyberjaya • Damansara • Dengkil • Ijok • Jenjarom • Jeram • Jugra • Kajang • Kalumpang • Kapar • Kerling • Klang • Kuala Kubu Bharu • Kuala Selangor • Kuala Sungai Buloh • Kuang • Kundang • Lagong • Meru • Morib • Padang Jawa • Pandamaran • Paya Jaras • Port Klang • Puchong • Rasa • Rawang • Sabak • Salak Tinggi • Sekinchan • Selayang • Semenyih • Sepang • Serendah • Seri Kembangan • Sijangkang • Subang • Sungai Ayer Tawar • Sungai Besar • Sungai Buaya • Sungai Buloh • Sungai Choh • Sungai Pelek • Sungai Pelong • Tanjung Harapan • Tanjung Karang • Tanjung Sepat • Teluk Datok • Teluk Gong • Teluk Panglima Garang • Ulu Klang • Ulu Yam • Alam Budiman • Alam Impian • Ara Damansara • Bandar Baru Bangi • Bandar Baru Klang • Bandar Baru Selayang • Botanic • Bukit Tinggi • Country Homes • Kinrara • Mahkota Cheras • Saujana Putra • Seri Putra • Sri Damansara • Bandar Sultan Suleiman • Sungai Buaya • Sungai Long • Sunway • Tasik Puteri • Bandar Tun Hussein Onn • Bandar Utama • Bernam Jaya • Bukit Antarabangsa • Bukit Beruntung • Bukit Jelutong • Bukit Rahman Putra • Bukit Rimau • Bukit Subang • Country Heights • Damansara Jaya • Damansara Perdana • Damansara Utama • Denai Alam • Eco Grandeur • Elmina • Glenmarie Cove • Hillpark • i-City • Jade Hills • Kelana Jaya • KLIA Charter Field Town • Kota Kemuning • Kota Puteri • Lembah Beringin • Lembah Jaya • Mutiara Damansara • Pandan Indah • Pandan Jaya • Puncak Alam • Puncak Perdana • Putra Heights • Saujana Impian • Setia Alam • Southville City • Subang Jaya • Berkeley • Taman Cuepacs • Greenwood • Hillview • Keramat • Melawati • Putra Perdana • Sri Andalas • Sri Muda • Taman Tun Teja • TTDI Jaya • UEP Subang Jaya • Valencia • Bagan Nakhoda Omar • Dusun Tua • FELDA Soeharto • Kampung Bukit Lanchong • Kampung Desa Serdang • Kampung Kuantan • Kampung Lombong • Kampung Sungai Haji Dorani • Kampung Sungai Kayu Ara • Kampung Sungai Pusu • Kuala Kubu Bharu (Ampang Pechah) • Kundang • Pulau Meranti • Tanjung Dua Belas • Carey Island • Pulau Indah • Pulau Ketam • Klang Island • Pulau Jemor • Pulau Angsa • MSC Malaysia • Klang Valley Perak: Bagan Datuk, Batang Padang, Hilir Perak, Hulu Perak, Kampar, Kerian, Kinta, Kuala Kangsar, Larut, Matang, Selama, Manjung, Mualim, Perak Tengah, Ipoh, Batu Gajah, Taiping Pahang: Bentong District, Bera District, Cameron Highlands District, Jerantut District, Kuantan District, Lipis District, Maran District, Pekan District, Raub District, Rompin District, Temerloh District, Bandar Bera, Bandar Muadzam Shah, Bandar Tun Abdul Razak, Bandar Tun Razak, Batu Hitam, Batu Talam, Belimbing, Benta, Bentong, Beserah, Brinchang, Bukit Ibam, Bukit Tinggi, Ceruk Paluh, Chendor, Chenor, Cheroh, Fraser's Hill, Gambang, Gebeng, Genting Highlands, Genting Sempah, Jerantut, Karak, Kemayan, Kerdau, Ketari, Kota Iskandar, Kota Shahbandar, Kuala Lipis, Kuala Pahang, Kuala Rompin, Kuala Tahan, Kuala Tembeling, Lanchang, Lentang, Lubuk Paku, Lurah Bilut, Maran, Mengkarak, Mengkuang, Mentakab, Merapoh, Nenasi, Paloh Hinai, Panching, Pekan, Penor, Raub, Sebertak, Sempalit, Sungai Lembing, Sungai Ruan, Tanah Rata, Tanjung Lumpur, Tanjung Sepat, Teluk Cempedak, Temerloh, Teriang, Tringkap Melaka: Alor Gajah Asahan Ayer Keroh Bemban Durian Tunggal Jasin Kem Trendak Kuala Sungai Baru Lubok China Masjid Tanah Melaka Melaka Merlimau Selandar Sungai Rambai Sungai Udang Tanjong Kling Terengganu: Besut District • Dungun District • Hulu Terengganu District • Kemaman District • Kuala Nerus District • Kuala Terengganu District • Marang District • Setiu District • Ajil • Bandar Al-Muktafi Billah Shah • Bandar Ketengah Jaya • Bandar Permaisuri • Bandar Seri Bandi • Batu Rakit • Bukit Besi • Bukit Payong • Chukai • Jabur • Jerangau • Jerteh • Kampung Raja • Kemasik • Kedai Buluh • Kerteh • Kijal • Kuala Besut • Kuala Berang • Kuala Dungun • Kuala Jeneris • Kuala Telemung • Marang • Merchang • Paka • Pasir Raja • Rantau Abang • Rasau Kerteh • Teluk Kalung • Wakaf Tapai • Alam Serada • Rantau Petronas • Jenagur • Kampung Tok Imam Lapar • Padang Midin • Rusila • Seberang Takir • Sekayu • Sungai Bari • Wakaf Mempelam • Bidong • Kapas • Lang Tengah • Perhentian • Redang • Tenggol • Wan Man Kelantan: Bachok District • Gua Musang District o Lojing Autonomous Sub-District • Jeli District • Kota Bharu District • Kuala Krai District • Machang District • Pasir Mas District • Pasir Puteh District • Tanah Merah District • Tumpat District • Bachok • Bukit Bunga • Bunut Payong • Dabong • Gua Musang • Jelawat • Jeli • Ketereh • Kota Bharu • Kuala Krai • Kubang Kerian • Lojing • Machang • Manek Urai • Pasir Mas • Pasir Puteh • Pengkalan Chepa • Pengkalan Kubor • Pengkalan Pasir • Perupok • Rantau Panjang • Salor • Tanah Merah • Temangan • Tok Bali • Tumpat • Wakaf Bharu • Wakaf Che Yeh • Bandar Utama Gua Musang • Bandar Baru Tunjong • Bandar Chintawangsa • Bandar Pasir Puteh Sentral • Bandar Saujana Harmoni • Bandar Satelit Islam Pasir Tumboh • Bandar Tasek Raja Negeri Sembilan: Jelebu • Jempol • Johol • Rembau • Sungai Ujong • Tampin • Jelebu District • Jempol District • Kuala Pilah District • Port Dickson District • Rembau District • Seremban District • Tampin District • Ayer Kuning • Air Kuning Selatan • Ampangan • Bahau • Bandar Seri Jempol • Batang Benar • Batu Kikir • Chembong • Chengkau • Dangi • Gemas • Gemencheh • Johol • Juasseh • Kota • Kuala Klawang • Kuala Pilah • Labu • Lenggeng • Linggi • Lukut • Mantin • Mambau • Nilai • Pajam • Paroi • Pantai • Pasir Panjang • Pedas • Pengkalan Kempas • Pertang • Port Dickson • Rantau • Rasah • Rembau • Rompin • Senawang • Sepang Road • Seremban 2 • Seremban 3 • Seri Menanti • Serting • Sikamat • Siliau • Simpang Durian • Simpang Pertang • Sungai Gadut • Sungai Muntoh • Tampin • Tanjung Ipoh • Teluk Kemang • Tiroi • Bandar Ainsdale • Bandar Baru Nilai • Bandar Enstek • Bandar Springhill • Bandar Sri Sendayan • Rasah Jaya • Seremban Forest Heights • Taman Seremban Jaya • Taman Tuanku Jaafar FELDA L.B. Johnson • Bukit Pelanduk Johor: Ayer Baloi, Ayer Hitam, Ayer Tawar, Bandar Penawar, Bandar Tenggara Batu Anam Batu Pahat Bekok Benut Bukit Gambir Bukit Pasir Chaah Endau Gelang Patah Gerisek Gugusan Taib Andak Jementah Johor Bahru Kahang Kluang Kota Tinggi Kukup Kulai Labis Layang-Layang Masai Mersing Mersing Muar Nusajaya Pagoh Paloh Panchor Parit Jawa Parit Raja Parit Sulong Pasir Gudang Pekan Nenas Pengerang Pontian Pulau Satu Rengam Rengit Segamat Semerah Senai Senggarang Seri Gading Seri Medan Simpang Rengam Sungai Mati Tangkak Ulu Tiram Yong Peng Perlis: Arau Kaki Bukit Kangar Kuala Perlis Padang Besar Simpang Ampat Pulau Pinang: George Town • Penang Island • Seberang Perai • Northeast Penang Island • Southwest Penang Island • North Seberang Perai • Central Seberang Perai • South Seberang Perai • Air Itam • Balik Pulau • Batu Ferringhi • Batu Kawan • Batu Lanchang • Bayan Lepas • Bukit Mertajam • Butterworth • Gelugor • Jelutong • Kepala Batas • Nibong Tebal • Paya Terubong • Perai • Permatang Pauh • Pulau Tikus • Simpang Ampat • Sungai Jawi • Tasek Gelugor • Tanjung Bungah • Tanjung Tokong • Teluk Bahang • Teluk Kumbar • Alma • Ayer Rajah • Bandar Baru Air Itam • Bagan Ajam • Bagan Dalam • Bagan Jermal • Bagan Luar • Bandar Cassia • Bandar Perda • Bandar Tasek Mutiara • Batu Maung • Batu Uban • Bayan Baru • Bukit Jambul • Bukit Minyak • Bukit Tambun • Bukit Tengah • Ceruk Tok Kun • Green Lane • Juru • Kampong Serani • Kampung Siam • Kota Permai • Mak Mandin • Minden Heights • Mount Erskine • Penaga • Penanti • Pinang Tunggal • Relau • Rifle Range • Seberang Jaya • Seri Tanjung Pinang • Sungai Ara • Sungai Dua • Sungai Dua • Sungai Nibong • Sungai Pinang • Taman Free School • Taman Tun Sardon • Teluk Air Tawar • Valdor • Berapit New Village • Gertak Sanggul • Jawi New Village • Kampung Buah Pala • Kampung Selamat • Kampung Seronok • Kubang Semang • Machang Bubok New Village • Mengkuang Titi • Pantai Acheh • Permatang Damar Laut • Permatang Pasir • Permatang Rambai • Permatang Tinggi • Sungai Acheh • Sungai Lembu • Sungai Udang • Teluk Tempoyak • Aman • Betong • Gedung • Jerejak • Kendi • Lovers' • Penang • Rimau • Tikus Sikalastic 841 ST, Sikalastic 8800, Sikalastic 851, Mapei Purtop 1000, Mapei Purtop 600, Fosroc polyurea WPE, Fosroc polyurea WH 200, Fosroc polyurea FLM, Fosroc polyurea WCS, Quickseal MP250, Quickseal MP500, Quickseal PP350, Quickseal Reflect Silver, Quickspray Industrial W, Quickspray Supreme AL, Quickspray Supreme W, Quickspray Supreme HE, Quickseal PP350, Quickspray Supreme HP, Quickfloor 400, Quickfloor 500, Quickfloor 500 V, Quickspray Supreme HP Kedah: Baling District • Bandar Baharu District • Kota Setar District • Kuala Muda District • Kubang Pasu District • Kulim District • Langkawi District • Padang Terap District • Pendang District • Pokok Sena District • Sik District • Yan District • Alor Tajar • Anak Bukit • Baling • Bedong • Bukit Kayu Hitam • Bukit Pinang • Bukit Selambau • Changlun • Durian Burung • Guar Chempedak • Gurun • Jeniang • Jitra • Kepala Batas • Kodiang • Kota Sarang Semut • Kuah • Kuala Kedah • Kuala Ketil • Kuala Nerang • Kuala Pegang • Kulim • Kupang, Kedah • Langgar • Lunas • Megat Dewa • Merbok • Padang Matsirat • Padang Serai • Pendang • Pokok Sena • Semeling • Serdang • Sik • Siong, Kedah • Sintok • Sungai Lalang • Sungai Limau • Sungai Petani • Sungai Seluang • Tanjung Dawai • Tawar, Baling • Tokai • Yan • Bandar Laguna Merbok • Bandar Puteri Jaya • Bandar Darulaman • Lagenda Height • Bandar Baru Mergong • Tandop Baru • Bandar Amanjaya • Bandar Stargate • Bandar Starcity • Bandar Sejahtera • Bandar Ambangan Sarawak: Betong Division • Bintulu Division • Kapit Division • Kuching Division • Limbang Division • Miri Division • Mukah Division • Samarahan Division • Sarikei Division • Serian Division • Sibu Division • Sri Aman Division • Asajaya District • Bau District • Belaga District • Beluru District • Betong District • Bintulu District • Bukit Mabong District • Dalat District • Daro District • Julau District • Kabong District • Kanowit District • Kapit District • Kuching District • Lawas District • Limbang District • Lubok Antu District • Lundu District • Marudi District • Matu District • Meradong District • Miri District • Mukah District • Pakan District • Pusa District • Samarahan District • Saratok District • Sarikei District • Sebauh District • Selangau District • Serian District • Sibu District • Simunjan District • Song District • Sri Aman District • Subis District • Tanjung Manis District • Tatau District • Tebedu District • Telang Usan District • Padawan municipality • Kuching • Miri • Asajaya • Ba'kelalan • Balingian • Bario • Batu Kawa • Batu Niah • Bau • Bekenu • Beladin • Belaga • Belawai • Betong • Biawak • Bintangor • Bintulu • Dalat • Daro • Debak • Engkilili • Julau • Kanowit • Kapit • Kota Samarahan • Lawas • Limbang • Lingga • Lubok Antu • Lundu • Maludam • Marudi • Matu • Mukah • Oya • Pakan • Pusa • Sadong Jaya • Saratok • Sarikei • Sebauh • Sebuyau • Selangau • Sematan • Serian • Serikin • Sibu • Siburan • Simunjan • Song • Spaoh • Sri Aman • Sungai Tujuh • Tanjung Kidurong • Tanjung Manis • Tatau • Tebedu Sabah: Interior Division • Kudat Division • Sandakan Division • Tawau Division • West Coast Division • Beaufort District • Beluran District • Keningau District • Kinabatangan District • Kota Belud District • Kota Kinabalu District • Kota Marudu District • Kuala Penyu District • Kudat District • Kunak District • Lahad Datu District • Nabawan District • Papar District • Penampang District • Putatan District • Pitas District • Ranau District • Sandakan District • Semporna District • Sipitang District • Tambunan District • Tawau District • Telupid District • Tenom District • Tongod District • Tuaran District • Beaufort • Beluran • Keningau • Kinabatangan • Kota Belud • Kota Marudu • Kuala Penyu • Kudat • Kunak • Lahad Datu • Nabawan • Papar • Pitas • Putatan • Ranau • Sandakan (Municipality) • Semporna • Sipitang • Tambunan • Tawau (Municipality) • Telupid • Tenom • Tongod • Tuaran • Banggi • Inanam • Kemabong • Kiulu • Likas • Membakut • Manggatal • Menumbok • Pagalungan • Paitan • Sepanggar • Tamparuli • Tanjung Aru • Tungku • Bingkor • Bongawan • Donggongon • Gum-Gum • Kimanis • Kalabakan • Kinarut • Kundasang • Lok Kawi • Long Pasia • Pensiangan • Sapulut • Sindumin • Sook • Telipok • telaga air, perigi air, shimge, ebara, xylem, tsunami, SWA Water Malaysia, Exyte, BIM modelling, Veolia, Suez, Gradiant, biological treatment, anaerobic treatment, aerobic treatment, anoxic treatment, UASB, gas flare, heavy metals removal, multistage treatment, chemical treatment, Cepietso, Cepswam, bacteria treatment, sewage treatment, IWK, wastewater operation services, lab analysis, IETS, DOE standard A and Standard B, written notification, Second schedule, Third Schedule, endorsement, Lamella Clarifier, DAF system, coagulant, PAC, A-Polymer, C-Polymer, Caustic Soda, Sulphuric Acid, jar test,

bacteria treatment, sewage treatment, IWK, wastewater operation services, lab analysis, IETS, DOE standard A and Standard B, written notification, Second schedule, Third Schedule, endorsement, Lamella Clarifier, DAF system, coagulant, PAC, A-Polymer, C-Polymer, Caustic Soda, Sulphuric Acid, jar test, caustic soda, PAC, ferric chloride, A-polymer, C-Polymer, sludge dewatering, solid liquid separation, sulphuric acid, hydrogen peroxide, advanced oxidation process, sustainability, green energy, energy saving, recycling wastewater, reclamation system, retrofits and upgrades, laundry wastewater, oil and gas wastewater, dairy wastewater, industrial wastewater, water treatment, reverse osmosis system, nanofiltration, sand filtration, activated carbon filtration, project management, filter press, screw press, decanter, UASB, anoxic process

Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer

Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer

Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer

Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer

Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer

Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer

Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer

Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer

Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer

Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer

Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer

Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer

Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer

Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer

Sectional panel tank Malaysia, glass fused to steel tank Malaysia, glass reinforced polymer tank Malaysia, GRP tank Malaysia, fibre reinforced polymer tank FRP tank Malaysia, hot dip galvanised tank Malaysia HDG tank Malaysia, Bomba tank Malaysia, potable water storage tank, storage tank Malaysia, pressed steel tank Malaysia, Pipeco Malaysia, Panel Tank Supplier, Stainless steel tank Malaysia, Stainless steel sectional tank Malaysia, epoxy coated cylindrical tank Malaysia, composite stainless steel tank, YMC Technologies Sdn Bhd, Permastore, Balmoral, CST glass fused to steel tanks, Tank Tech Sdn Bhd, Tank Team Sdn Bhd, biogass holder, glass fused to steel tank, fusion bonded epoxy (FBE) steel tank, anaerobic reactor, double membrane biogas holder, DIN 4102 B1 standard, CH4 gas, ground mounted double membrane biogas holder, center enamel, Fusion Bonded Epoxy Tanks, Stainless Steel Bolted Tanks, Galvanized Steel Tanks, Aluminum Geodesic Dome Roofs, Storage Tank Roofs, Vegetable Oil Storage Tanks, Grain Storage Tanks, Rainwater Harvesting System, Wastewater Treatment, Drinking Water Storage Tanks, Installing Epoxy Bolted Tanks, Welded Steel Tanks, spiral tank, Bulk Material Storage Tanks, Grain Storage Tank, Fire Protection Water Tanks, Oil Tank Floating Roofs, Crude Oil Storage Tanks, Gas Storage Tanks, Malstore Sdn Bhd, HDPE lining tank, lipp tank, Spirolite Sdn Bhd, SPAN, SIRIM, JANS, PBA Sarawak, Suruhanjaya Perkhidmatan Air Negara, Jabatan Kerjaraya, Jabatan Bekalan Air, liquid containment, Circular HDG Steel Bolted Tank with HDPE Wall Lining, Glass Coated/ Glass Fused/ Epoxy Coated/ Epoxy Lining Steel Water Tank, American Water Works Association Standards (AWWA D103-87/97/09), Steel Panels: BS4360/JIS3101 Grade SS400, Hot Deep Galvanized Coating (HDG): Grade BS729, Stainless Steel Bolted Tanks Glass Lined Steel Tanks Bolted Steel Tanks Biogas Storage Tanks Drinking Water Tanks Agricultural Water Tanks Dry Bulk Storage Tanks Potable Water Tanks Process Water Tanks Wastewater Tanks Anaerobic Digesters Leachate Tanks Municipal Sewage Tanks Fire Water Tanks Industrial Water Tanks Grain Storage Silos Agricultural Silos Liquid Storage Tanks Fire Sprinkler Water Tanks Industrial Liquid Tanks China Storage Tanks Manufacturer China Stainless Steel Water Tanks Manufacturer